MicroAM will introduce the following novel, key elements, which we foresee to be essential to the future of metal AM:

- A laboratory-based X-ray microscope capable of mapping local residual stress non-destructively in 3D with a spatial and strain resolution better than 5 μm and 5×10−4, respectively.

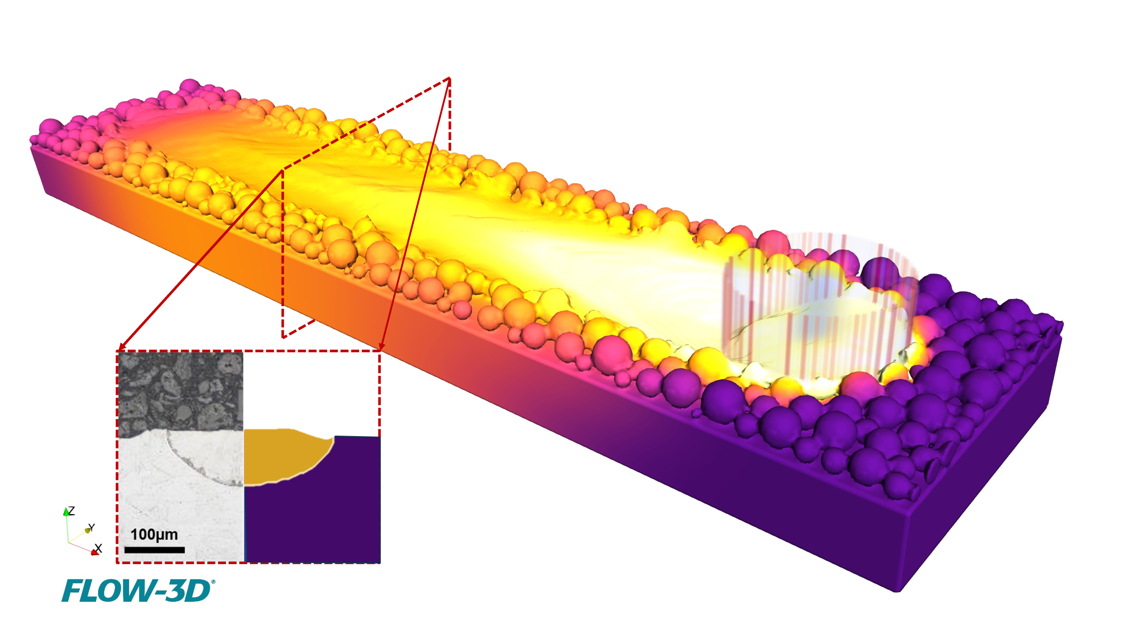

- A multi-scale AM process–microstructure–property–performance simulation platform that includes models for simulations of the microstructural dynamics for all of the following stages:

1) during the AM process,

2) while exposed to post-AM stimuli (as selected for microstructural engineering), and

3) when loaded during in-service operation. - A theoretical framework that includes the effects of multi-scale voids and local residual stresses in microstructural engineering, and that addresses the local microstructural evolution during exposure to mechanical, thermal and corrosive stimuli/loads, thus laying the foundation for design of AM-defect tolerant microstructures.

- An exploitation of the microstructural engineering potential for AM of metals by two demonstration cases.