In 2022, Chief Engineer at Grundfos John Jacobsen flew to Singapore, bringing with him a big question: Why had several of the pumps that ensure cooling in large office towers in Asia stopped working one to two years after installation?

The pumps are part of the so-called distributed pumping system, and in Europe the same pumps have for decades provided hot water circulation to heat many buildings. Through distributed pumping, the pumps distribute an exact amount of water on all floors of a building, avoiding wasting energy by heating and distributing more water than is needed.

The same principle is used for cooling buildings, where the pumps distribute cool water instead of hot water. In 2019, Grundfos delivered the first pumps to be included in systems for cooling office buildings in Singapore and Hanoi, among other places.

“Our pumps do not require maintenance. We have integrated the motor and pump into the so-called impeller, which means you do not need to renovate or replace the bearings. In theory, they can last indefinitely,” says John Jacobsen.

So why did a significant number of pumps stop working only a few years after installation in Asia?

Shorted diode

John Jacobsen returned to Denmark, bringing some of the pumps that had stopped working, and now the investigation work could begin.

Grundfos identified the failed component in the pump: A diode that was shorted. Diodes are small electronic components that can be used to rectify the current. The shorted diodes were located in the power supply for the pumps’ control electronics.

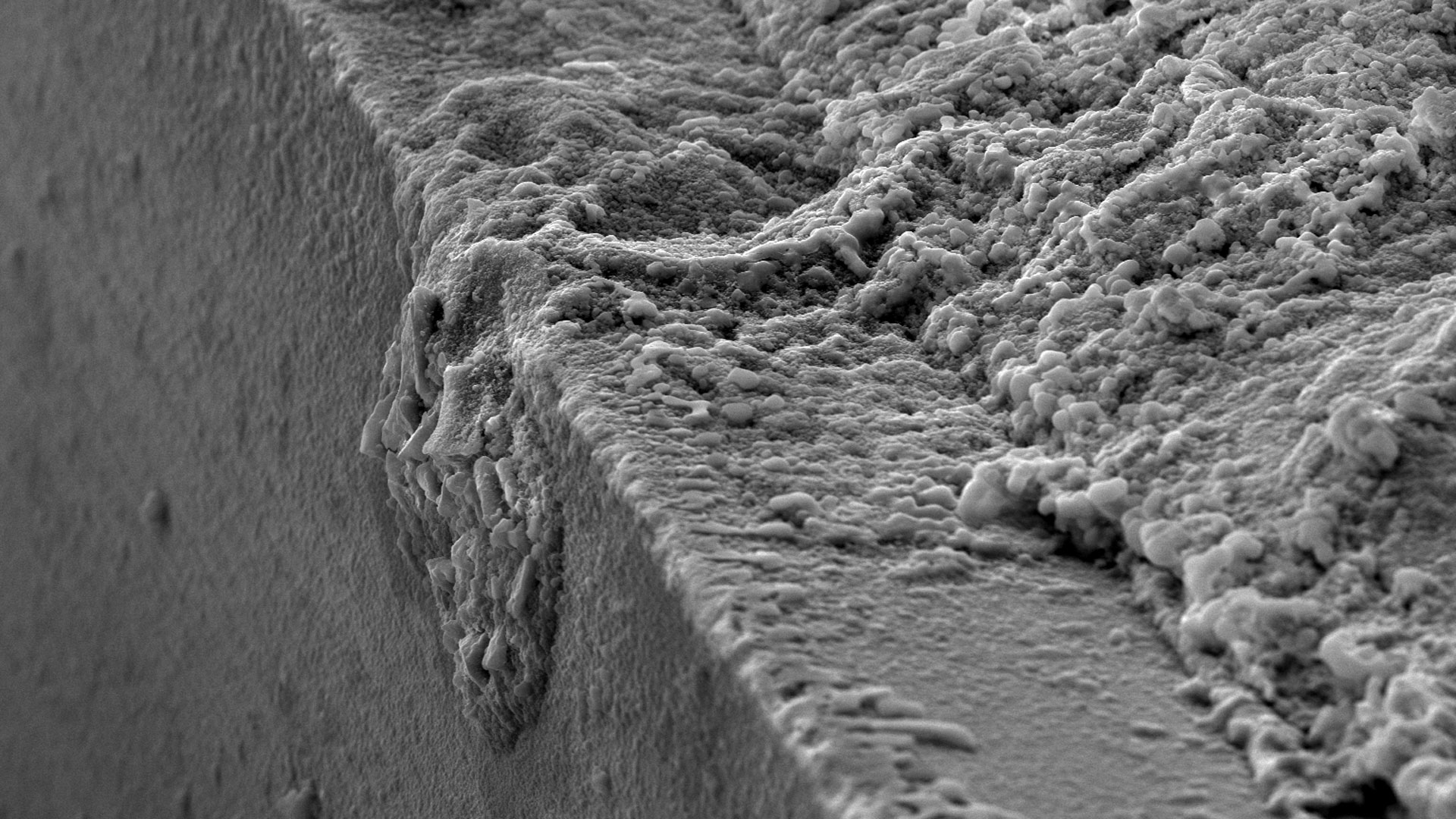

Grundfos shared their discovery with the Asian supplier of the diodes, who took the matter very seriously and started examining the failed diodes closely. They found that the short-circuits were caused by an electro-chemical migration of material inside the diode. This means that some material has been able to ‘migrate’ because it has been exposed to a combination of moisture and an electric field.

“We needed more knowledge to fully understand what had happened to the diode and what material had migrated, so we could prevent similar incidents in the future. We needed more documentation,” says John Jacobsen.

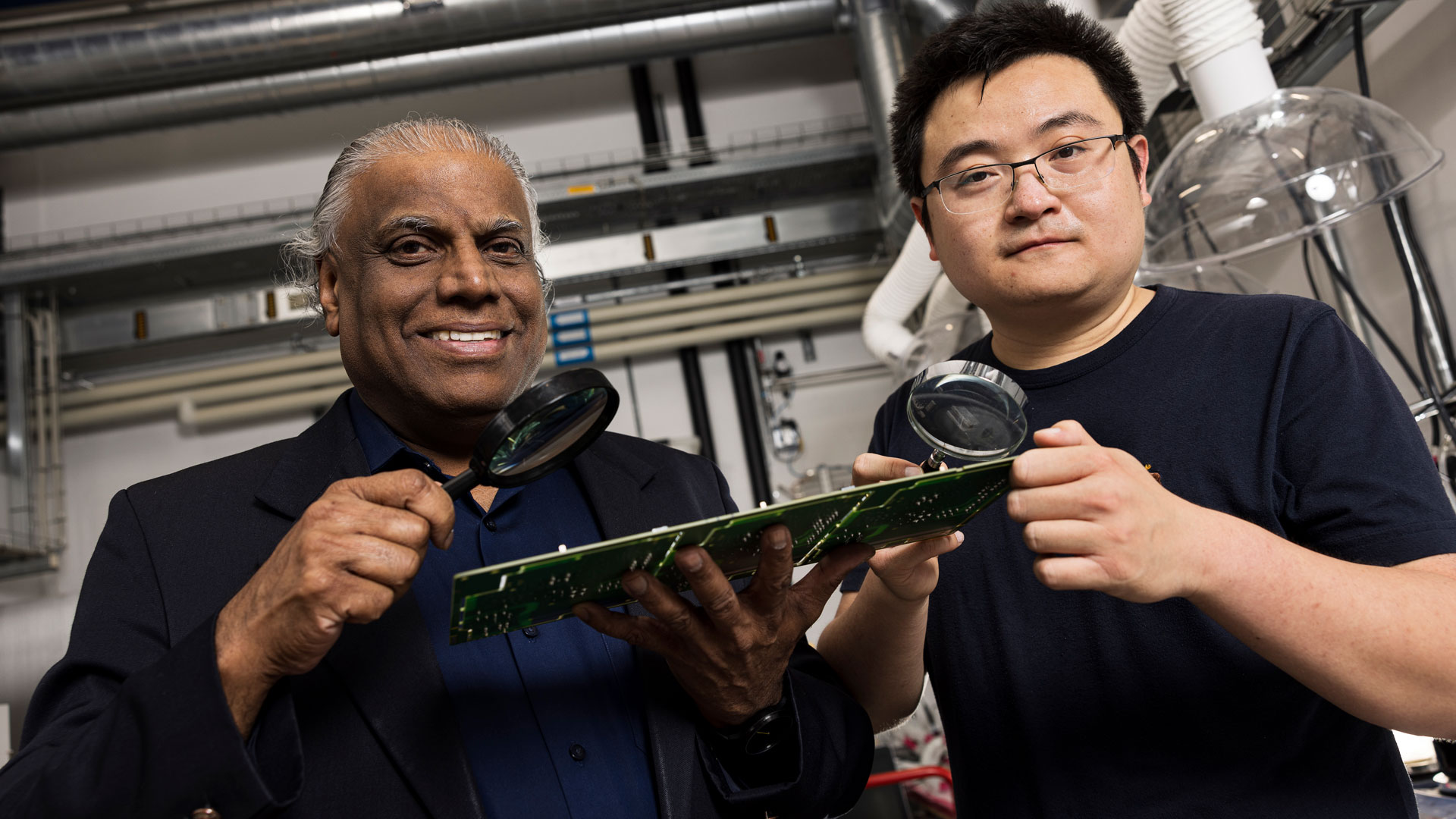

This prompted John Jacobsen to contact Rajan Ambat, Professor at DTU Construct and head of the Center for Electronic Corrosion (CELCORR). The two have collaborated since 2011 in the CreCon consortium, established by Rajan Ambat. CreCon brings together several Danish and international businesses and DTU’s subject matter experts in the field of corrosion in electronics. In addition to gaining access to the latest knowledge and leading corrosion experts, businesses can also ask for help from DTU researchers when corrosion is suspected in electronics.

Corrosion problems on the rise

Corrosion is unwanted degradation of metals and alloys Most of us know corrosion as rust, which is often just a visible phenomenon on surfaces and something that only changes the appearance of the surface. But there’s more at stake when the phenomenon occurs inside electronics.

“When electronics is subjected to corrosion, it can fail in a split second. So whether the electronics is in a wind turbine, a solar cell, an electric car, a mobile phone, or laptop, you risk that the product immediately stops working. It can go really fast - sometimes as little as 30-60 minutes from when corrosion occurs until the electronics fails,” says Rajan Ambat.

The professor explains that corrosion in electronics is an increasing problem, and that several factors are driving this upward trend:

“We’re integrating electronics into more and more products, and they are exposed to very different conditions. Just think of offshore wind turbines and solar cells, both of which contain electronics, but are exposed to very different weather conditions. Increasing humidity is also a factor that challenges electronics, and in cities we have increasing problems with pollution with sulphur and nitrogen oxide gases from car traffic, which can also settle in electronic components and cause corrosion. In addition, the electronics components are constantly getting smaller and smaller, and the shorter the distances between electrical circuits, the less moisture or material is needed to create unwanted connections that lead to short circuits,” explains Rajan Ambat.

So which of these factors was at play in the diodes inside the pumps in Asia?

Important history

The first thing that Rajan Ambat and his colleagues always do when helping a business is meet with them to get a detailed account of the circumstances surrounding an issue. This was also the case when they received the inquiry from John Jacobsen from Grundfos.

“It’s very important for us to understand the history of the failed component and know all the other factors: Where is the component included, how is it used, and how long has it been in use? Grundfos is very careful to document such things. This information helps us to hypothesize as to the reason for the error, and we can discuss which methods we should use to investigate the component and find documentation that can confirm our hypotheses,” says Rajan Ambat.

After the meeting with Grundfos, Rajan Ambat and his colleagues received some of the diodes that had failed and went to the laboratory to examine them further.

“Our studies are based on our knowledge of materials. When corrosion takes place, it’s always about materials. The materials used in the electronics have been impacted to behave in an undesirable way,” says Rajan Ambat.

Since the faulty diode in the Grundfos pump was completely embedded in the protective material epoxy, the researchers initially had to try to remove this material using chemicals that could dissolve it. Unfortunately, it affected the diode itself, so it was not suitable for the analysis.

“It made us wonder if there was another and non-destructive way to examine the diode,” says Rajan Ambat.