DTU Mechanical Engineering has recently received a funding of 2.6 million kr. from by the European Commission within the 7th Framework Programme (FP7) to work with the HINMICO project (High Throughput Integrated Technologies for Multimaterial Functional Micro Components). The project as a whole has received fundings for 29.000.000 kr. from FP7.

The purpose of the project is to develop more cost efficient production processes of multi material micro products by increasing the process capability and the production quality of the micro injection moulding process. The project aims at solving the different problems that exist today in relation to the industrial production of multi material micro products.

Challenges in micro production are related to time consuming and expensive quality control and assembly operations where 35 – 60 % of the production expenses are due to the assembly of the products, which is often performed manually.

New micro factory machine

HINMICO will develop a new micro factory machine which will integrate mass production of multi-material products, micro injection moulding, automated micro assembly, in-line 3D quality control and inspection, process monitoring and 100% total quality micro manufacturing. Precision engineering, surface quality and the interaction between the different materials of the products are also important areas of focus and challenges which the project will aim to investigate.

The project will have a strong impact for precision manufacturing companies active in the production of micro mechanical systems for medical applications (e.g. implants, hearing aid systems), telecommunication and sensors technologies.

Collaboration between DTU Mechanical Engineering and industry partner Ortofon

DTU Mechanical Engineering, Section for Manufacturing Engineering, will contribute to HINMICO with expertise in the fields of process chain design, micro moulding process development and monitoring, quality control and metrology. DTU Mechanical Engineering will work in close collaboration with the Danish industrial partner of the project, the company Ortofon A/S, a world-leader in the field of precision engineering and micro production, to develop the HINMICO new micro factory concept.

Guido Tosello is project leader.

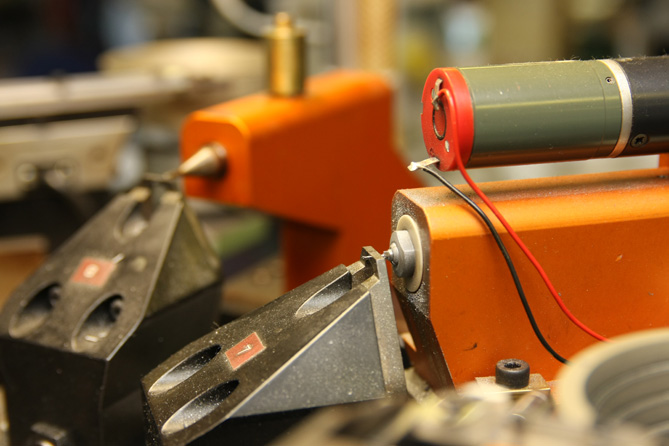

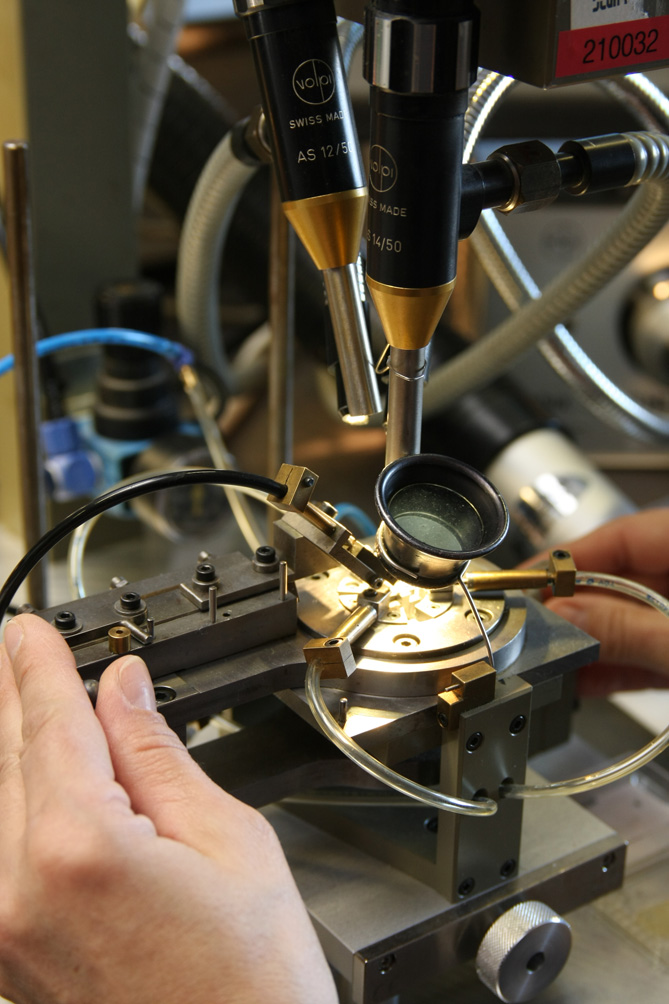

Pictures from the collaborating partner, Ortofon:

Moving magnet cartridges production, Ortofon.

Moving coil cartridges production, Ortofon.